- Manufacturing

- Jun 07

How to Decide whether to Accept or Reject the lot in Manufacturing Scenarios?

Suppose in an organisation, when we have to evaluate the quality of incoming or outgoing products – “How we do it?” Based on certain quality characteristics – “How we make a decision whether to accept or reject the lot?”

The answer lies behind the concept of “Acceptance sampling”. It is an alternative to 100% inspection. Here, inspection is performed on a lot or batch of parts or products. We can use acceptance sampling to accept or reject a lot based on a representative sample. It plays a major role in the quality control process.

Please keep in note that acceptance sampling doesn’t improve the quality of a process but it helps to control quality to a great extent. It helps in decision making whether to accept or reject lots.

Some of the benefits are

- Easy to understand

- Cost-effective method

- Reliable results

- More economical

- Time-saving

Basic Terms

- Lot size – It is the entire set of items/observations from where samples are drawn.

- Sample size – It is the number of items that are drawn randomly from a lot for inspection.

- Acceptance number – It is the maximum number of defects or defectives that are allowed in an acceptable lot.

- Acceptable Quality Level (AQL) – It is the highest proportion of defectives in a lot or batch that is considered acceptable. It describes “What the sampling plan will accept?”

- Rejectable Quality Level (RQL) – It is the highest defective rate that the consumer is willing to tolerate in a lot. Lots at this level are considered to be poor and have a low probability of acceptance. It describes “What the sampling plan will reject?”

Which method to use: Attribute sampling plan or Variable sampling plan?

It depends on which types of data we are dealing with. If it is an attribute type of data, we will go for Attribute sampling plan and if it is a variable data, we will go for Variable sampling plan.

- Attribute sampling plan – This sampling plan is used to accept or reject a lot based on the number of defects or defectives (discrete data) in a sample. For example, you receive a lot of 5000 capacitors and by this method, you will be able to determine the sample size (how many capacitors you need to inspect) and acceptance number (how many defects are allowed within the sample).

- Variable sampling plan – This sampling plan is used to accept or reject a lot based on variable data (continuous data) such as length, thickness, diameter, hardness, etc. For example, you receive a lot of 3000 pistons and you need to verify that the diameter meets specifications. By this method, you will be able to determine the sample size (how many pistons you need to inspect) and criteria for accepting or rejecting a lot (critical distance).

Since we have discussed the basic concepts of acceptance sampling. Now, I would like to move a little forward and discuss the risks involved in acceptance sampling.

You must be thinking, “Why risks are involved?” Let me remind you, we are not doing 100% inspection – we are taking a sample from a lot for inspection.

There are two types of risks involved while doing it –

- Producer’s risk – It is represented by α. We might reject good lots which should be accepted. Thus, creates a lot of problems for the producer. It is also known as type I error.

- Consumer’s risk – It is represented by β. We might accept bad lots which should be rejected and creates problem to the consumer. It is also known as type II error.

NB – Want to learn, How to run Acceptance Sampling Analysis in Minitab Software? Attend our Minitab Certified Training Program, starting from basic to advanced level. Some of the Minitab software training certified courses are Minitab Essentials, Statistical Tools for Pharmaceuticals, Statistical Quality Analysis & Factorial Designs, etc. Apart from Minitab training, we also conduct basic and advanced Statistical training. Some of the Statistical training certified courses are Predictive Analytics Masterclass, Essential Statistics For Business Analytics, SPC Masterclass, DOE Masterclass, etc.

We also provide a wide range of Business Analytics Solutions and Business Consulting Services for Organisations to make data-driven decisions and thus enhance their decision support systems.

Related Posts

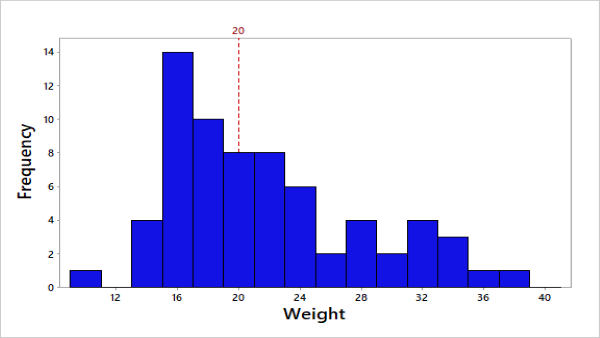

What can we Discover from the Process Data by Creating a Simple Histogram?

A simple demonstration of Histogram usage in your process! Histogram is commonly used for graphical….

- Oct 05

Is your Sample Size enough for doing the Analysis?

I guess this is an important question we should ask ourselves before doing any kind of analysis. We should…

- Jul 06

Categories

Recent Posts

- What role do t-tests play in Pharmaceutical Processes? When can we apply it?

- How Data Science can help to Improve the present Healthcare Scenarios?

- What can we Discover from the Process Data by Creating a Simple Histogram?

- What are the Quality Tools Available in Minitab?

- Why Choose Minitab as your Statistical Data Analytics Software?