- Manufacturing

- Oct 05

What can we Discover from the Process Data by Creating a Simple Histogram?

A simple demonstration of Histogram usage in your process!

Histogram is commonly used for graphical representation of numerical data. Most importantly, it is one of the basic quality improvement tools used in various industrial processes.

What is a Histogram?

A Histogram is a graphical representation of data where data values are shown in rectangular bars which shows the occurrence (frequency) of data values on numerical intervals of equal size.

By plotting histogram, we can examine the shape and spread of our process data. I would like to highlight the terms “shape” and “spread”. The shape of a histogram can help us to determine whether the data is normal or not. While the spread of histogram can help us to determine variability in data.

Now, let’s demonstrate one simple example – How can we use the histogram in manufacturing process scenarios?

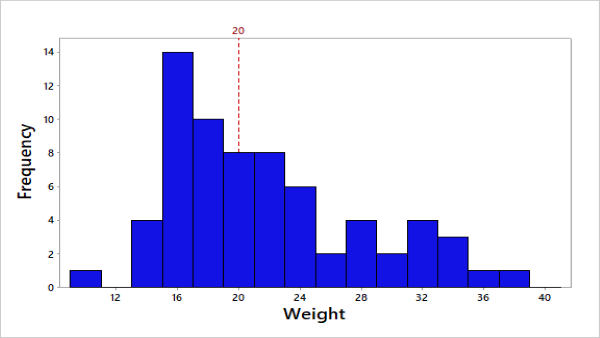

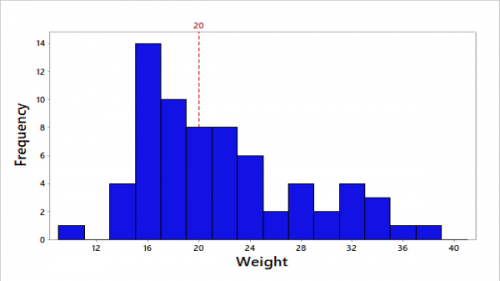

Suppose in a Battery Manufacturing Industry, a quality control engineer needs to ensure that the process is producing the plates within the target value. The target plate weight value is 20 kg. Since plate dimension is an important factor in the battery manufacturing process.

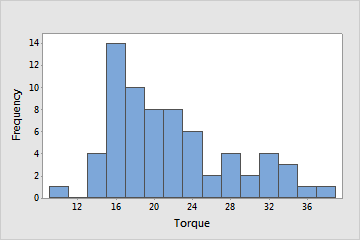

The engineer collects a sample of 75 plates by random sampling and measures the weights of it. From the measured data, a simple histogram is created.

Now, my question for you – “Whether this process is producing a plate within the target weight value or not?” So, what will be our interpretation….

Here, a greater number of plates were produced with a plate weight of 14 to 24. But our target value is 20. Moreover, many plates were beyond the target. Therefore, this process is bad and have to work for improvement.

I guess this brief example will help you to understand the usage of a histogram in your process.

Benefits

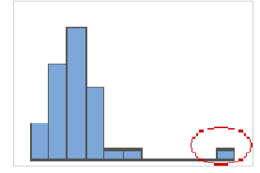

- Identification of outliers – Outliers are high or low values that are apart from other data points.

- Visual representation – It gives an overall outlook of a process data which is simple to grasp.

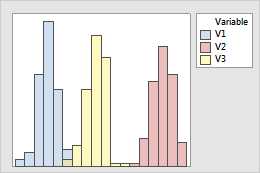

- Comparison – We can use a histogram to compare the output of different processes.

Some important considerations

- Sample data should be collected randomly.

- Sample size should be more than 20.

NB – Want to know more about Histogram and Applications in Industries? Attend our Statistical Training Program starting from basic to advanced level. Some of the Statistical training certified courses are Predictive Analytics Masterclass, Essential Statistics For Business Analytics, SPC Masterclass, DOE Masterclass, etc. Apart from Statistical training, we also conduct Minitab Certified Training Program, starting from basic to advanced level. Some of the Minitab software training certified courses are Minitab Essentials, Statistical Tools for Pharmaceuticals, Statistical Quality Analysis & Factorial Designs, etc.

Related Posts

Is your Sample Size enough for doing the Analysis?

I guess this is an important question we should ask ourselves before doing any kind of analysis. We should…

- Jul 06

How to Decide whether to Accept or Reject the lot in Manufacturing Scenarios?

Suppose in an organisation, when we have to evaluate the quality of incoming or outgoing products – “How we do it?”

- Jun 07

Categories

Recent Posts

- What role do t-tests play in Pharmaceutical Processes? When can we apply it?

- How Data Science can help to Improve the present Healthcare Scenarios?

- What can we Discover from the Process Data by Creating a Simple Histogram?

- What are the Quality Tools Available in Minitab?

- Why Choose Minitab as your Statistical Data Analytics Software?

Recent Comments